After the glass bottle is made, according to the different needs of customers, various patterns, symbols, colors, etc. need to be added to the surface of the bottle, which requires different surface treatment processes to achieve. The commonly used process treatments include baking, frosting, spraying, engraving, screen printing, electroplating, polishing, etc.

1) Baking

First print the pattern on the baking paper made of special materials, and then stick the baking paper with the pattern on the glass bottle. After drying, put it into the electric heating baking furnace for heating and cooling. The pattern is printed on the glass surface. Its adhesion is very strong. Baking is divided into high temperature and low temperature.

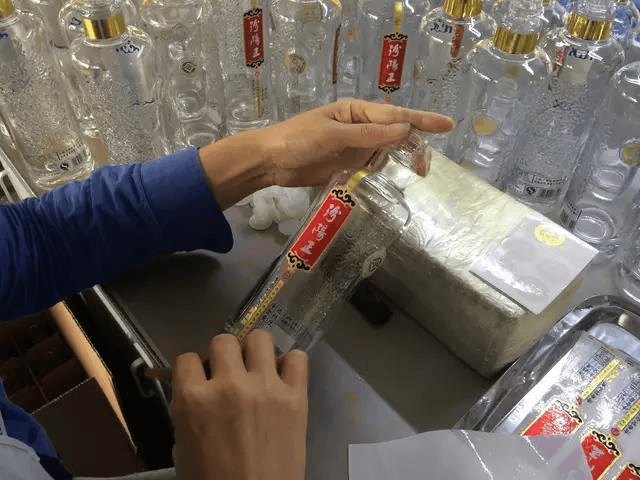

Factory baking site:

2) Frosting

Frosting is to soak the glass bottle in a solution prepared in glass frosting powder to corrode the surface of the glass bottle to produce a hazy effect, or use glass powder and glass bottles for high-temperature sintering to achieve the effect of environmentally friendly frosting. Frosting is divided into full frosting, partial frosting, and hollow frosting.

Frosting process display:

3) Sandblasting

Sandblasting is a process that uses compressed air as a power source to form a high-speed jet beam, spraying abrasives (quartz sand, corundum, etc.) at high speed onto the surface of the glass to be processed, causing physical changes on the surface. Due to the impact and cutting action of the abrasive on the surface, it obtains a certain degree of cleanliness and different degrees of roughness. After sandblasting, the surface of the glass bottle forms a hazy, noble and elegant visual effect, and it also feels better. The surface of the glass bottle can not only be partially frosted, but also sprayed with various patterns and texts.

Sandblasting process display:

4) Color spraying (spraying)

The color spraying process is also called spraying, which uses a special glass paint, sprays it evenly on the surface of the glass bottle with a spray gun, and then dries it. Glass bottle spraying is divided into high temperature and low temperature according to temperature. Now high temperature is rarely used due to environmental protection, energy consumption and other reasons; glass bottle spraying is divided into transparent color and solid color (bright and matte) according to color: according to the spraying part, it is divided into gradient spraying and full spraying; there are also spraying with mixed colors. It should be noted that a glass bottle can have multiple processes at the same time, not just one.

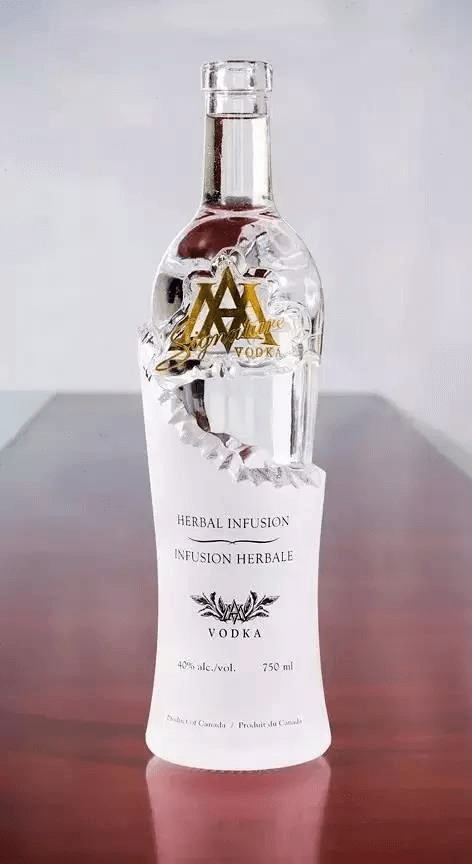

Spraying process display:

In addition to the processes introduced above, common glass processes include electroplating, screen printing, thermal transfer, etc.

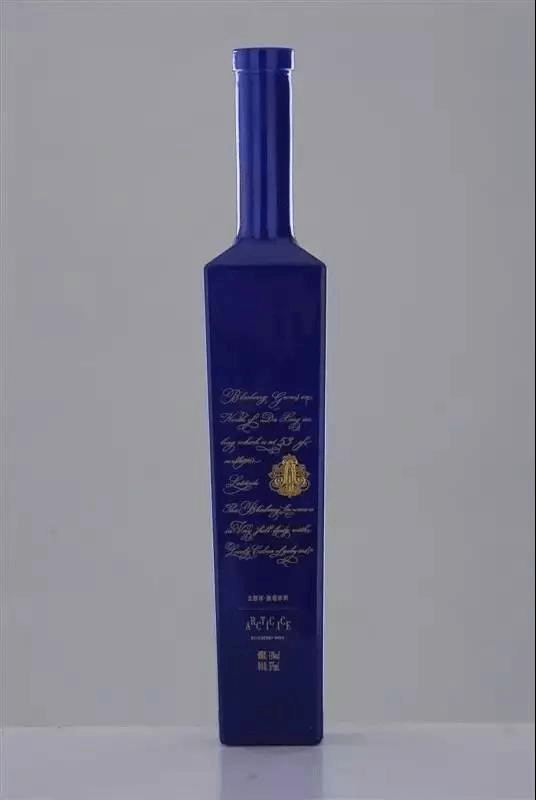

Electroplating process display:

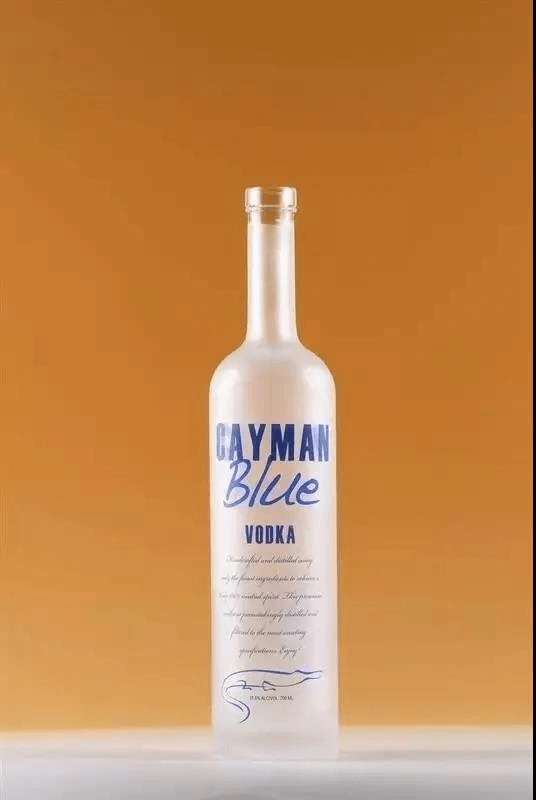

Screen printing process display:

After looking at the display pictures of the above process effects, I believe everyone has a more intuitive understanding of the glass bottle process.

Copyright @ 2025 Kaipu Glass Products (Jiangsu) Co., Ltd All Rights Reserved.

Network Supported

Network Supported

Sitemap / Blog / Xml / Privacy Policy